The test method shall be conducted for minimum requirements for the installation of cable tray system applied as follows: The number of single or multi-conductor cables rated 11kV, 6.6kV, 1kV or less in cable trays shall include an allowance of 20% extra space for future expansion.

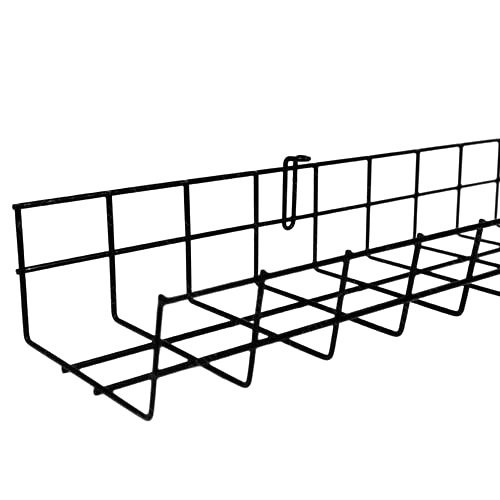

Cover fabrication shall be the same as that of cable trays themselves and shall be fixed on cable trays with proper clips recommended by cable tray Manufacturer/Vendor and comply with project required specification.ĩ. Cable trays shall be provided with covers where there is high risk of mechanical damage during normal operation or maintenance periods. All cable trays shall be perforated or ladder type to avoid the retention of water and to allow fastening of the cables.Ĩ. Cable tray installation shall be designed to carry a load of 100kg/m. Distance between fixing points and cable tray support spacing shall be a maximum of three meter for ladder type tray and two meter maximum for perforated tray so as to avoid strain on cable trays.ħ. Cable trays shall be fixed onto standard steel shapes, welded to steel structures or fixed on to concrete structures with self-drilling dowels. On pipe racks, cable tray shall run on the top most level(s).Ħ. On horizontal cable trays, laid flat cables are fixed in group (one fastening for every two or three meters). On vertical cable trays and on edgewise – horizontal cable trays, each cable shall be fixed with 20mm wide stainless steel strips (two per meter). Only in special cases shall cable trays be installed vertically or on edge. Tray shall run as far as possible under flooring and walkways.

Cable tray installation shall preferably be installed flat in buildings or operating structures.

0 kommentar(er)

0 kommentar(er)